QA / QC by Gedin

8 May 2019

Gedin developes and implementes a 1st- and 2nd-line quality control for a concrete factory in the Netherlands and Germany.

One of our clients is working on the renovation of a large historic steel arch bridge. The bridge consists of two bridges on pillars and a main span across the Waal. The steel bridge has a concrete deck and asphalt on top. As part of the renovation, the entire bridge deck is removed and the steel structure is preserved again. After this a new bridge deck is applied in the form of prefab concrete slabs on which a very thin layer of asphalt (30 mm) is applied.

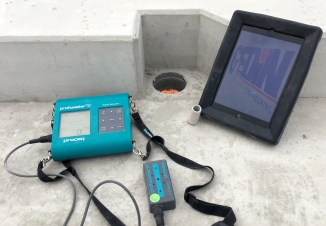

The prefab concrete slabs are produced in a contractor's factory. Due to the large span and the increased traffic load in recent years, the weight of the new concrete deck needs to be optimized. The prefab concrete slabs are designed by the contractor to be as light and strong as possible. Among other things, the design offers very precise tolerances with regard to the coverage of the reinforcement in the slabs. An adequate and traceable check of the reinforcement cover is important for the structural safety of the bridge.

At the request of our client, Gedin has set up, implemented and carried out 1st and 2nd line quality control.

Quality Assurance

A start has been made on making an inventory of the inspection requirements. Based on this, an inspection plan / matrix has been set up. The most important contractual and technical design requirements are guaranteed in this plan. Among other things, use was made of the expertise of the involved constructor and work planners. The inspection plan is made available via an online tool, in this case ED Controls (https://edcontrols.nl), for the 2nd line tester who performs the inspections.

Quality Control

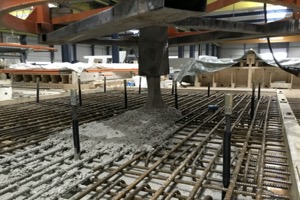

Prior to the production of the concrete slabs, a check is made of the landfill. The reinforcement included herein is assessed on various aspects. In case of rejection, measures are taken where possible on the spot, so that the production process is delayed as little as possible.

Once the coffin and the reinforcement have been approved, a dumping release is made, the concrete can be poured.

After the plate has hardened, the crate is removed and a final inspection takes place. Here too, various aspects are assessed. Any imperfections are recorded and, where necessary, control measures are established and implemented.

< Summary